UNDERSTANDING BYBORRE: A QUEST TO MASTERING KNIT

BYBORRE is a pretty tough brand to describe – but not for a lack of things to say.

Sure, you might be able to string together a timeline of their initial years, you may even be able to cast predictions for the Amsterdam powerhouse, but bring to life what’s core to the brand? Virtually impossible.

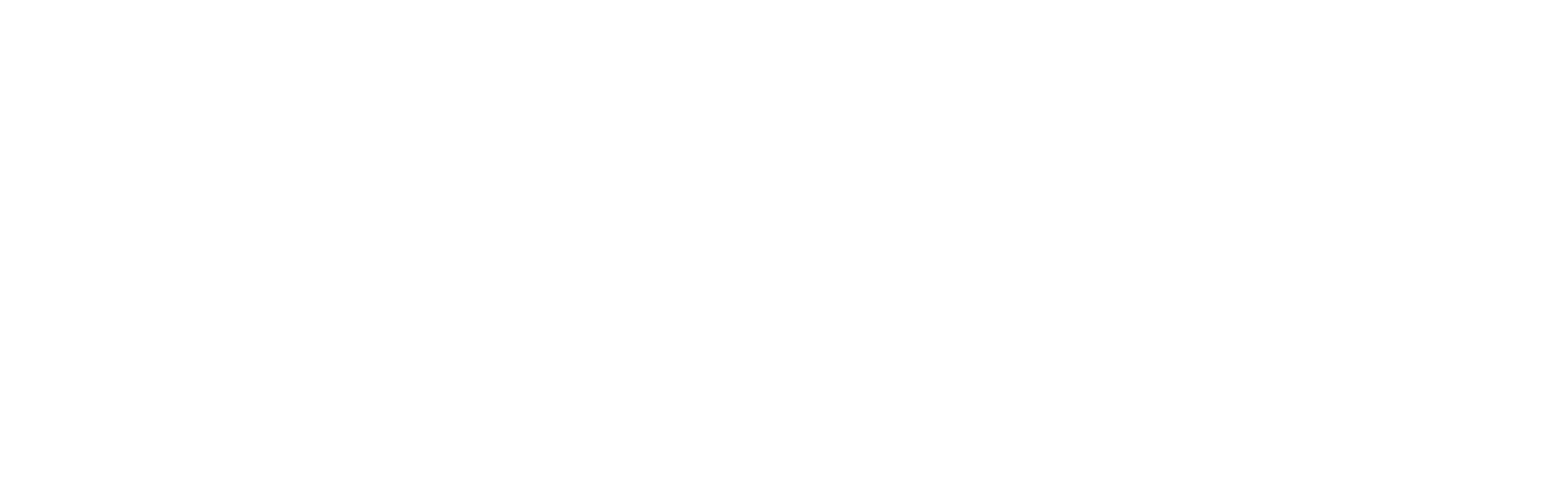

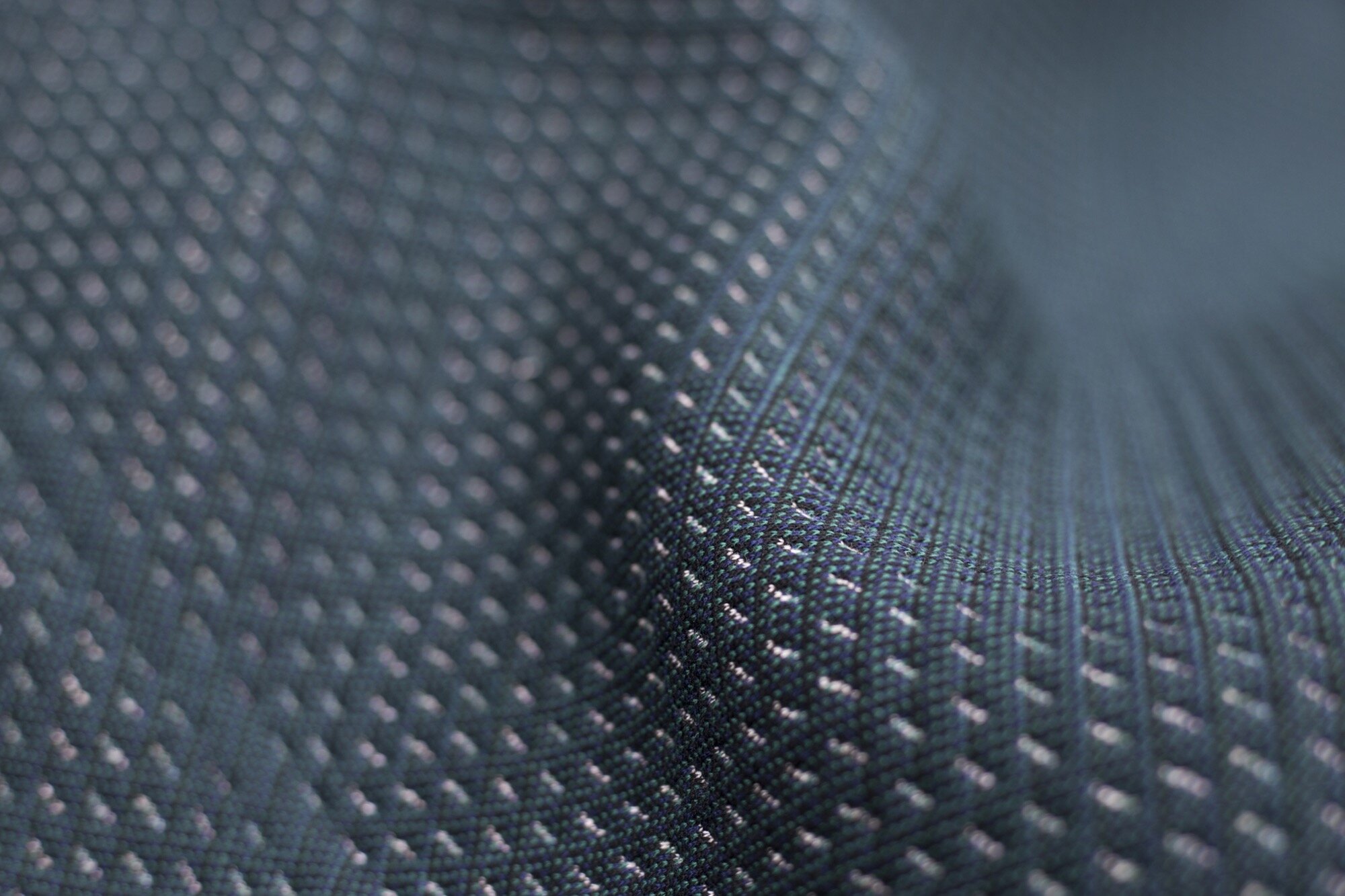

To better articulate the BYBORRE brand, you must first experience the sensation behind it all:

The Knit Technology. Its feel and weight can only be experienced for itself. Seek out the fabric, feel it, touch it, and you will understand.

BYBORRE AW19: The Layered Edition™ @Petrovsky & Ramone

But BYBORRE is more than “just” a brand, and they don’t only make clothing. BYBORRE is a textile revolution AND a brand - two stories with two angles.

What the BYBORRE brand shows you today might also become part of something entirely different tomorrow through BYBORRE INSIDE. Today, BYBORRE may have a standalone identity, but tomorrow, it might also become part of your favourite label in a very unexpected way.

The BYBORRE brand label

THE BYBORRE INSIDE tag

Here is one way to visualize the nuanced BYBORRE approach: Think about the story of GORE-TEX.

The name is synonymous with terms like “waterproof” and “breathable membrane”. Nowadays the GORE-TEX logo has become much more than that. It’s turned into a brand itself, told through its technical legacy. The GORE-TEX letters are no longer there just to signify performance in a garment anymore - it’s now built in and interlaced with the brands that use their technology. In many cases, GORE-TEX has even become the namesake of their partner's garment. From a membrane-embedded in a piece of runway fashion in Paris, to big letters stamped on jackets and bucket hats for the inner city youth - it’s a technical story turned fashion.

Wearing Tomorrow Today

BYBORRE tells this story from the opposite angle:

The BYBORRE brand is an impressive and probably the most innovative fashion label out there right now, but at the same time it fulfills another purpose:

The BYBORRE brand is an experimental laboratory and a prime example of what’s possible on the frontiers of textile and material development as well as functional wear and knit technology.

From fashion to outdoor labels, even car seats – BYBORRE and BYBORRE INSIDE have the ability to revolutionise them all.

BMW presents i Interactions EASE at CES 2020 with bespoke BYBORRE interactive knits

The materials, techniques and technologies you witness and feel today while wearing BYBORRE have the potential to embed themselves into a whole host of other brands, and markets. Be on the lookout for a small BYBORRE INSIDE logo on your next favorite Japanese fashion garment, an arctic expedition kit, or even car seats – BYBORRE and BYBORRE INSIDE have the ability to revolutionise how we perceive and interact with a core element that we overlook all the time, the textiles themselves.

That should not downplay the brand’s own importance by any means. The designs are one of a kind, the comfort unbeatable, the look and feel of every piece of clothing unique without any similar competition or reference in the market. Their pants alone deserve a whole article.

BYBORRE SS20: The TDK Edition™

BYBORRE is a brand that represents innovation more than any other fashion label in the world right now. But the fashion world is just one layer, one stage, one chapter in the conversation the label has initiated.

The BYBORRE story has just started and will spread out to all kinds of markets, industries and technologies - wearing tomorrow today.

With this article we will attempt to get you closer to this one of a kind brand and shed light upon their quest to mastering knit through words, visuals, questions, and answers.

Please, read and then find a store near you, to feel and understand.

Foreword by Adrian Bianco

UNDERSTANDING BYBORRE: A QUEST TO MASTERING KNIT

In many industries, especially fashion, the terms innovation, responsibility, and sustainability are often thrown about carelessly. But what do those words truly mean to those that claim this? At times it feels more like a marketing ploy more than anything else. And at other times it’s as if brands are just clamoring to use these terms strictly with a herd mentality in mind. Only a few have fully made a commitment to follow through with what they say and have sunk their time and resources where it counts. We believe BYBORRE, the Amsterdam-based textile innovation studio, is the perfect embodiment of that ethos.

The Approach:

BYBORRE has an unfair advantage. They utilize fashion as a medium, but apply a technical approach to it. They are the intersection between fashion and technology. To them, one cannot exist without the other. This is the foundation of how they will inspire and influence the future of the textile industry. There’s an underlying understanding at BYBORRE that widespread change doesn’t occur overnight. It’s the countless hours invested into a myriad of experiments, it’s the fearless nature of the team to be willing to break boundaries in an industry seemingly rife with outdated processes, and most of all, it’s having the foresight to tackle a problem that’s never had a solution.

The BYBORRE founders Borre Akkersdijk and Arnoud Haverlag DSM Ginza @Tengo Kawatsura

The Machine & Knit:

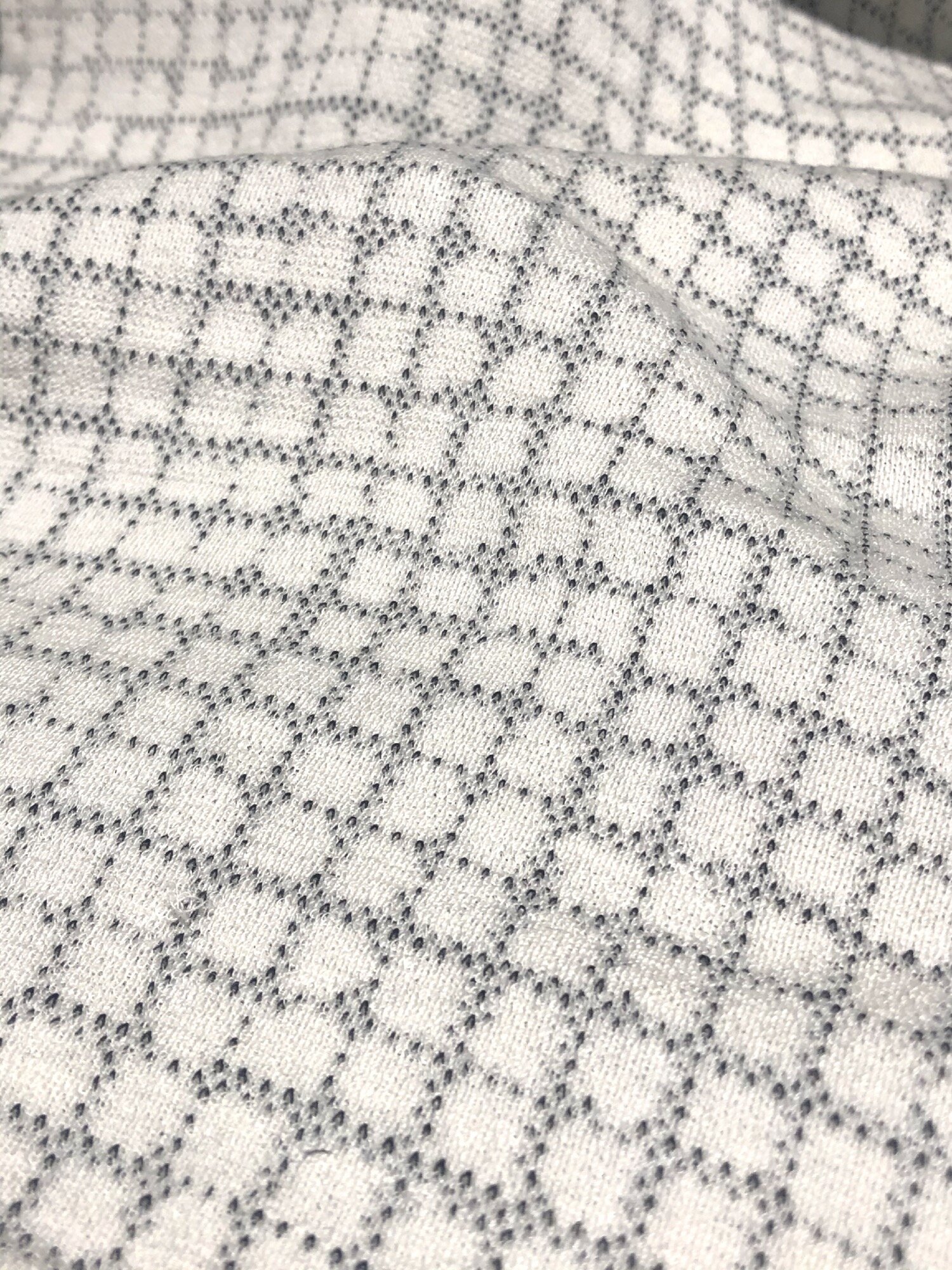

You can hear the roar of what lies lurking within BYBORRE’s Knit Lab just beyond the two white double doors that read “Restricted Area: Authorized Research Personnel Only”. As you enter, a wave of industrial heat washes over you and you spot four monster circular knitting machines towering over two meters tall. They’re adorned with numerous spools of yarn on top, steadily plugging away and constructing textured knits to their exact specifications.

The BYBORRE KnitLab

@ Charlie Duong

These circular knitting machines are the nucleus of BYBORRE’s iconic textiles. Utilizing techniques used primarily in the mattress industry, BYBORRE has completely retooled the programs for these machines. Whereas these were once a tool for mattress textile development, they are now utilized for a completely different custom function in order to change the conversation for the entire textile industry.

It’s truly a sight to behold. Mountains of boxes filled with yarn. The warm heat exterting from the machines. Yarns spinning and whirling into the center as the engineers oversee the entire process.

BYBORRE’s 8-bit material is the perfect example of the harmonious dance between the machine and textile. 8-bit comes from the eight yarn feeders of the circular knitting machine. Every feeder knits a single pixel, or bit, within the textile. Having complete and detailed control over the whole process means they’re able to engineer the textile from the yarn up, determining what yarn properties are needed in the outcome of the fabric seamlessly. With full control of the process and components of the textile, 8-bit is scalable and adaptable to the desired performance of any garment.

The Inside:

BYBORRE INSIDE follows a membrane approach, similar to that of GORE-TEX. There is recognition of guaranteed quality linked with the name. In the realm of GORE-TEX, creators understand that they can freely use the material without the looming constraints of having to make sure the garment is completely waterproof. The same approach can be applied to BYBORRE INSIDE, but the only difference is that creators have the ability to use BYBORRE technology to assemble textiles to their preferred performance specifications starting from the original base, the yarn.

Together with The Woolmark Company, BYBORRE recently explored and utilized the functionality of Merino wool fiber. Considered as the ancient performance fiber, Merino wool has exceptional breathability, odor resistance, and color dye adsorption.

A combination of Coolmax® and NILIT Heat yarn (an environmentally friendly yarn which infuses coffee charcoal from coffee bean shells into the nylon fiber) results in a fabric that is 75% Merino wool with enhanced breathability and moisture wicking properties. Designing from the yarn up, this is just one of many factors that could make up the blueprint of a garment with BYBORRE INSIDE.

SS20 TDK Edition™

To further delve into the brainstems of BYBORRE, we decided it’d be a good idea to chat with two of the masterminds, who dedicate their time on the frontlines working tirelessly to educate and change the perception of textile. We sat down with founder, Borre Akkersdijk and design director, Samuel de Goede to hear straight from the source, their take on the current climate of the industry, their values, latest work, design approach, and on their quest to mastering knit.

Text by Charlie Duong

A CONVERSATION WITH BYBORRE

BYBORRE, a brand driven by design and fabrics driven by innovation. How can we differentiate both stories and where are the points of contact?

B: The textile innovation studio is where we develop, design and iterate. We then produce unique iterations of the textile innovations we come up with for leading brands across industries ranging from high fashion to automotive and everything in between. It’s the start of something new.

The BYBORRE label functions as the showcase to bring new innovations to the world, as well as claim and protect our innovative textile developments. It is also where we can educate parts of the industry on the functionality and bigger potential of knit. It’s part of something bigger.

In the fashion and textile industry, BYBORRE’s passions lay in the overarching design perspective of materials and techniques. With your design background, how has it allowed you to look at the industry differently versus someone with a conventional fashion design background?

S: In our showcase we like to think that we take a product design approach. Fashion is simply the stage that we operate through. It’s a good place to be and a good place to tell our story . At BYBORRE, our overarching goal is to change the way the textile industry works. And one of the biggest players with a heavy influence in the textile industry is fashion. That’s the zoomed out view, but on a product design level, I think it’s much more about pieces slowly evolving. The main reason we still speak in seasons is due to the stage we decided to operate within works that way, and that’s hard to escape. For us it's about slowly evolving, testing out new ideas, and using them. Rather than spur of moment, trend-driven, creation which is commonly found in the fashion realm. We tend to shy away from that and focus on our own direction.

Do you find your design approach is more of an iterative process? Experimentation instead of throwing everything out and starting fresh everytime.

S: Very much so. When we start on a new Edition, which is how we title our label output, we literally build upon our families of textile innovations and our existing garment silhouettes and see what next steps we can take to further push comfort and performance.

BYBORRE EDITION 7™

Essentially to identify specific areas and see where innovation can happen. That’s a very technical approach.

S: If the design is there to give shape to the textile side, then the textiles in the lab are informing the outcome of the design side. How we approach our textile innovations in the lab also leads to construction solutions on the label side. We design using the same parameters, improving performance and comfort, reducing material waste and reevaluating every step along the way. There are certain things that have become our signature look, like the bias taping and framing. Both of these techniques came from figuring out ways to work with our materials that were beyond industry standards. As a result, next to the textiles this has become something we are recognized for, from a label perspective.

If we look at GORE-TEX in recent years, we can see a shift from a membrane to a brand. BYBORRE seems to tell this story from the opposite angle: a brand that explains the fabric. A brand that is rooted in innovation. Ultimately, would you say that BYBORRE is a messenger?

B: The label tells the story of understanding the end consumer and developing for them first on a yarn level, through to a textile level, and finally on a garment construction level. It is the perfect showcase of the ingredients being as important as the final product.

Innovation, cutting edge knitting techniques, performance wear, and technology. How can BYBORRE keep up such a fun and effortless organic “cool“ in this world of heavy wording?

B: It is not about the wording, it is about the love for what we do.

We created a place where we can really test, play, and make mistakes without losing time due to travel, importing/exporting goods long distances and relying on third parties to bring something new to the table.

We create and that is really what we do and that is the story we tell. It doesn’t get any more real than this.

Innovation and technology in fashion are usually told through usability and function. BYBORRE adds a sensational dimensional feeling. Someone that hasn't touched one of your fabrics simply can’t understand the wonders BYBORRE creates. What does that mean for your communication? And was your mobile showroom an answer to that

B: Thank you for this beautiful description. Our mobile showrooms were an answer to the crazy fashion cycle where there is hardly time for the new and innovative. In the last few years, the world has been run by hype culture. So we felt we had to bring our innovations to the people that we wanted to show too. Once people encounter the materials they can see and feel for themselves a fabric they have never experienced before. We let the textile, quality, and aesthetic do the talking.

Another beautiful characteristic of BYBORRE is color. What’s the doctrine behind your vibrant and intense colors and where are you heading to with it?.

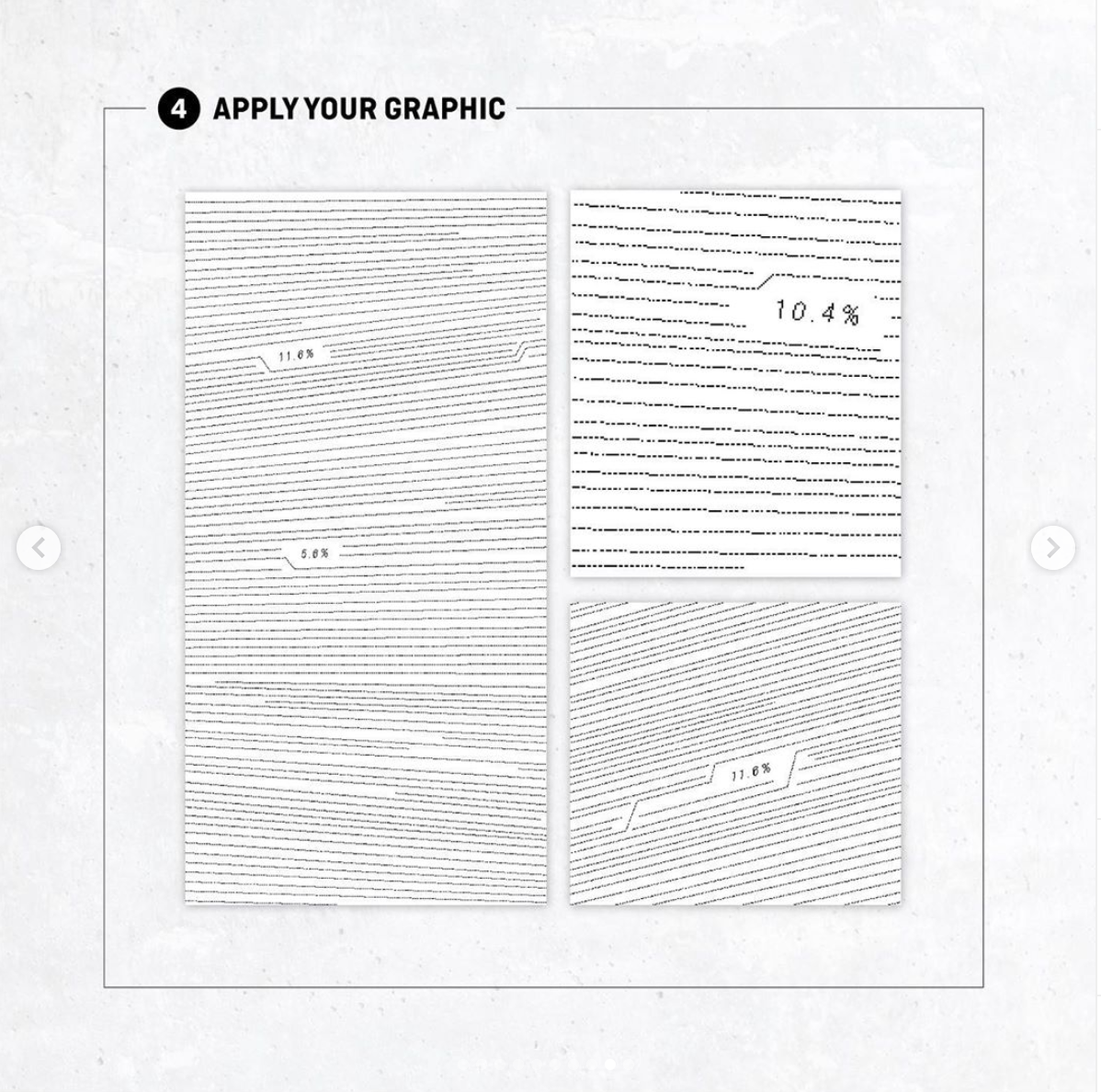

B: Color in life has depth and layers, it is never just a Pantone number. Of course, we start from color directions but working directly with our machines we developed a way through which the colors become very rich. It is a dialogue between the stitches and the amount of yarns you’re working with, as well as the program and the machine needed to create the textile. The mix of these variables gives an optical color with an incredible depth. We’ve evolved this way of working to the point that now it is part of our Textile Development Software, where we need minimal input to deliver deep and intriguing color solutions for the creators we work with.

BYBORRE AW19 The Layered Edition™

In this day in age, similar to greenwashing, the word “innovation” can sometimes be abused. What does true innovation and sustainability mean to BYBORRE?

S: We create with the “form follows function” approach and create an aesthetic or make space for an aesthetic interpretation. That’s pretty much what it boils down to. Our goal is to not take the standard as the status quo and the status quo as the standard, but rather, we're trying to push the boundaries of what people know to be doable on the machines they work with. Taking what people expect from a specific fabric or a specific garment and bringing that to another level. We call ourselves a textile innovation studio because that is the heart of what BYBORRE does. Looking back at what wasn’t possible and building on that with purpose, rather than creating something new just for the sake of saying something is new.

There is a purpose to it being new. In automotive terms, showing a concept car and letting everyone know that something like that is possible.

S: On the sustainability side, our approach focuses on looking at chains or stages that affect the sectors we operate in and seeing what can be improved upon there. An example of this is our True Color concept, which makes a bold statement to remove manufactured coloring through dyeing and instead use the actual, or true, color of the raw material. Something like that is our “concept car” approach.

With the BYBORRE label being the first client of our Knit Lab we also have a responsibility to showcase what is possible. Whenever we encounter something that excites us through our research and development, the label is the first to make or translate that switch and showcase it.

Adidas and BYBORRE present the TRUE COLOR design

B: For our generation, sustainability can not be a choice. It is a given and it should be a no-brainer. But that doesn’t make it easy for everyone to make the change. Everything BYBORRE does through the entire process, from the yarn to the end product, to everything we develop and every partnership we make has to be responsible. We want to lead by example and facilitate others to make those choices easier and straightforward.

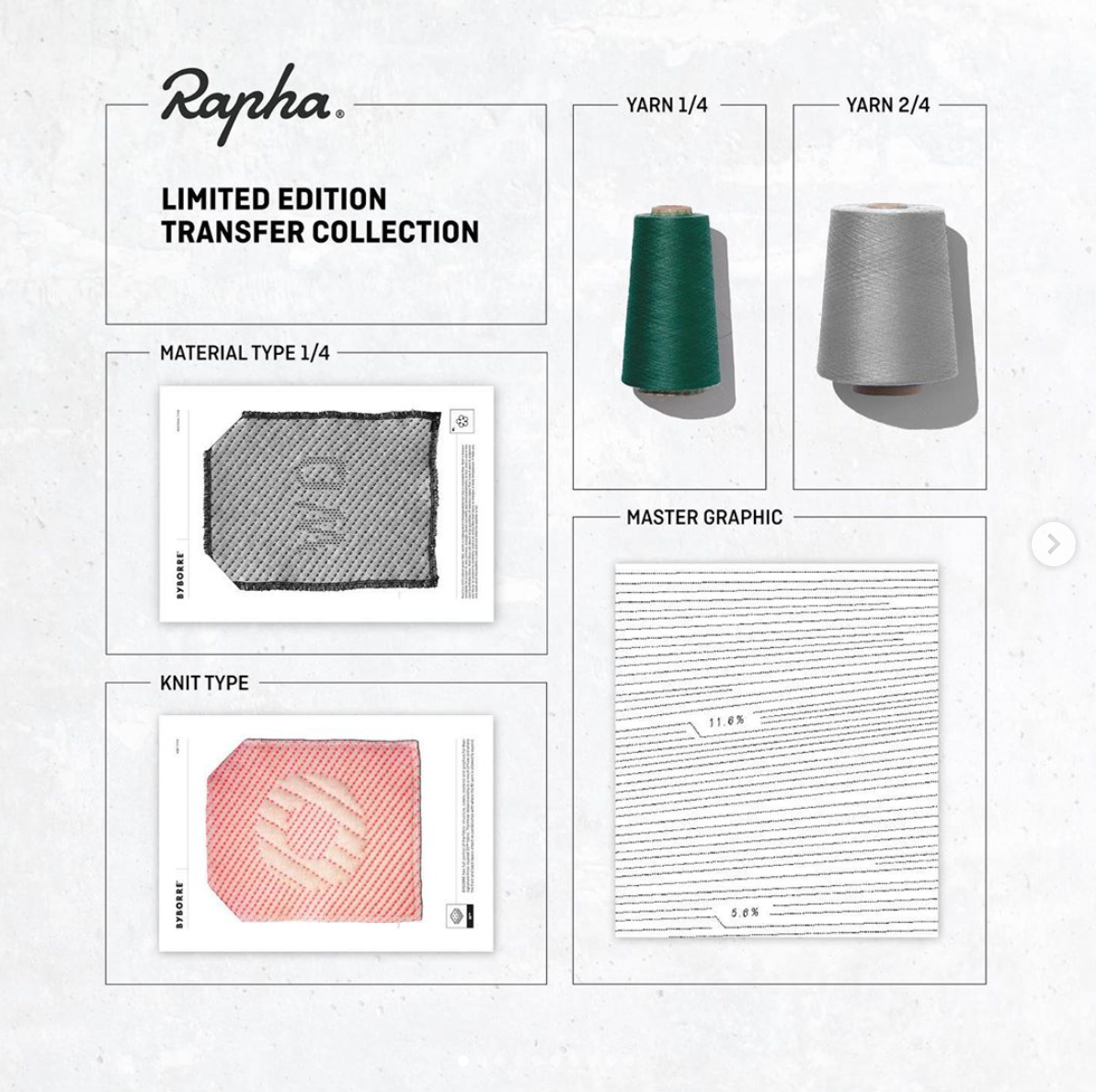

The next step within the BYBORRE world will be to open a virtual platform where we will open up all our responsible tools to designers, creators, and forward thinkers around the world. The Textile Development Kit (TDK)is our online software for creators that gives them the power to create more meaningful textiles for their end consumer in a responsible and sustainable way.

TDK TOOLBOX

In partnership with adidas, BYBORRE has created a design ideology called TRUE COLOR which aims to challenge the industry to use creative ways to reduce their environmental impact throughout each step of the design/creation process. Can you speak on what sparked this initiative, specifically with adidas? Has adidas learned any techniques from BYBORRE or vice versa?

S: It’s something that had been developed in-house already and we finally had the opportunity to use it in partnership with adidas. We've been thinking about how to best approach it and have been doing a lot of research into the concept. This partnership with adidas, was the right moment for both parties to introduce it to the world, using ISPO as a public stage to amplify the message to the industry.

At the heart of it, it’s essentially a design principle. We want it to be something that anyone can look at and use, whether you’re in marketing through to the creative side.

In the AW19 The Layered Edition™ collection, your hybrid concept reaches new heights by incorporating GORE-TEX and Woolmark into your garments. Can you please tell us more about the symbiosis of these three worlds and what this means for the final designs and products?

B: Our label is a showcase for our own textiles and ingredients, but it is also the perfect showcase to tell the story of our partners, which are the best ingredients in their own world. Within the label we have the chance to use these materials and create the best solutions with regards to construction of the textile or garment to give more functionality and comfort for the end consumer.

TDK (Textile Development Kit) is the new process used in BYBORRE’s SS20 collection. Taking inspiration from the development term, SDK (Software Development Kit) which helps to ease the creation of applications, how does BYBORRE’s TDK allow for ease of textile creation?

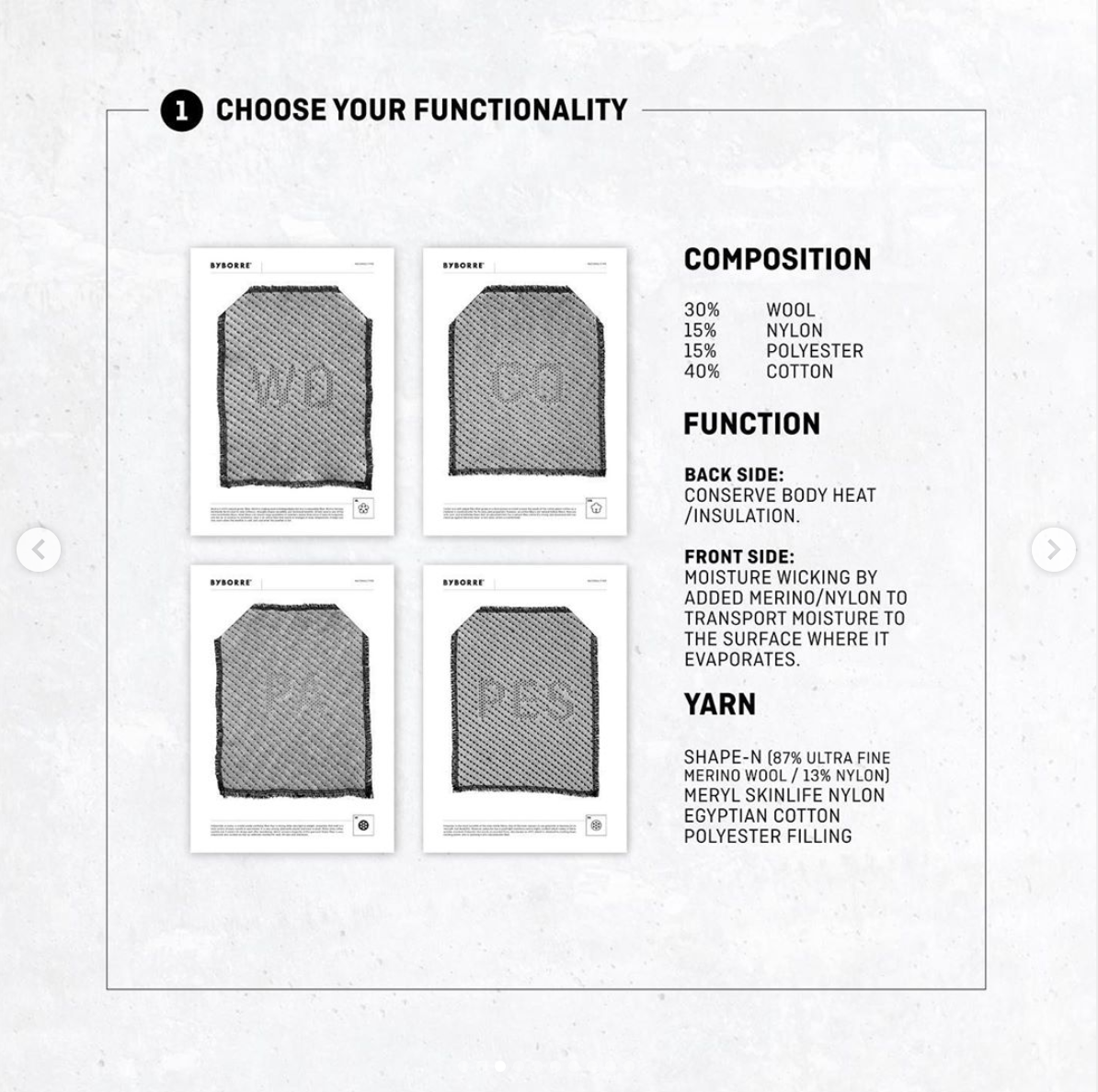

S: Designers currently face a complex process if they want to create a custom fabric. Our original idea was to develop the TDK for creatives and designers. We decided that we could break this process down to simple 4 steps, which are based on who you are designing for and what yarns correspond to your desired outcome...

Choose/outline your functionality and desired properties (functions that come from the yarn/material).

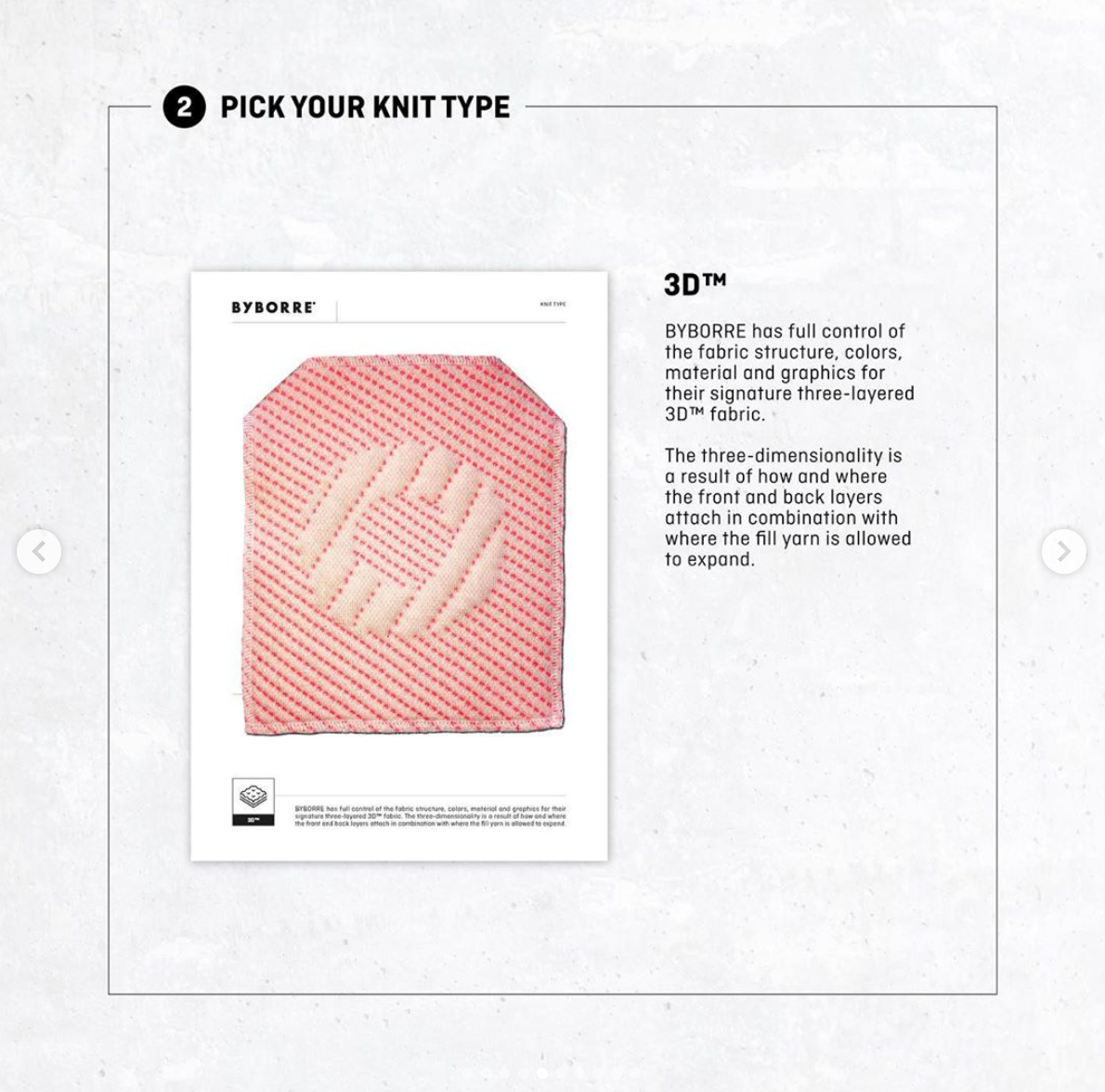

Choose your fabric type from BYBORRE’s Fabric Library (suited to the object you're designing the fabric for, e.g. base-layer, mid-layer, furniture, etc.) and based on this our experts can give suggestions.

Choose your color direction.

Add an artwork or your own graphical DNA / logo. At this step in the process, the designer can upload an image, an AI file, a JPG, and immediately order swatches.

These steps are radically different than how the industry normally works, which is very siloed, which are all not hard to access. At the end of the day these designers want to be creative and work with the best materials. This should be a tool for them rather than being a labyrinth that they need to navigate in order to get samples that need to be shipped back and forth across the world.

We are trying to eliminate this tedious, unsustainable back and forth and want to see if we can shift the industry to a more streamlined and localised approach. It’s about simplifying the process of how you get to actually be creative, as a creative.

On the label side, these are steps that we are already taking. With BYBORRE INSIDE, the projects where we develop for brands and clients, we open it up to the rest of the industry.

Where do you see the future of BYBORRE’s TDK within the industry? Do you see it as a sustainable best practice to textile creation which will be adopted industry wide?

S: The TDK software has been created to be a sustainable textile creation tool for creators around the globe.

With the “TDK Edition™”, we presented a showcase of how we used the TDK tool and steps to create our own sustainable textiles.

In our Showrooms in Paris and Tokyo we had a physical demo to explain the TDK and walk creators through the four development steps.

BYBORRE SS20: The TDK Edition™

This was an offline prototype of something that will soon be online.

Once our online tool is up and running, the driving wheel is back in the creator's hands and we are there to lend our expertise and advice to develop the desired samples. Descente ALLTERRAIN is a perfect example of a brand already working with our Textile Development Kit flow.

DESCENTE ALLTERRAIN & BYBORRE Mizusawa Down Jacket

BYBORRE has made a commitment to lead the way in best practices in textile innovation. What shifts in the industry and culture have you seen since the early beginnings of BYBORRE?

S: We are very much doing our own thing, but through being involved in many different sectors we have the opportunity to be at many different events showcasing our latest innovation.

Take ISPO for example, a large yearly performance and outdoor fair in Munich, where you can see that everyone is making it a priority to move forward more responsibly and sustainably.

adidas showcasing the True Color concept we developed at their ISPO booth shows the confidence they have in our ideas. Presenting it there as a joint design principle very much solidifies the intent of the big players. These small effects we are making are starting to show.

Next to this there is a lot happening around recycling, upcycling, material management, among others. Over the past couple years, the lines between events like Paris Fashion Week and ISPO have become more and more blurred. It makes sense that the outerwear side of things got embraced by fashion. Outerwear was already more focused on sustainability and responsibility just because they are all about being outdoors and nature itself.

The positive byproduct of this is that fashion is finally paying attention to that side of the industry and realizing there is more happening there beyond just the aesthetics. It is great to see brands becoming more transparent and holding themselves accountable.

Congratulations on the BMW i Interaction EASE! As you’ve said Borre, from birth we are wrapped in textile. We interact with textile everyday in all types of capacities. How did the design process with BMW differ from your collaborations with clients such as adidas & Snowpeak ? Did BMW use BYBORRE’s TDK?

B: In short, all clients go through the same steps to create their own perfect textile, and it was no different with BMW. We walked them through the 4 steps of the Textile Development Kit flow, answering their questions on functionality and what textile family would suit their end product best. We then discussed the color direction and BMW’s artwork that they wanted the textile to have.

Of course automotive and furniture have specific requirements that differ then those used for garments but this means that they will be suggested different yarns and structures based on their desired functionality, but following the same steps.

BMW presents i Interactions EASE

Modern knitwear and knitting techniques were first properly introduced to us through running shoes and the sneaker world. But now BYBORRE helps us understand and really feel those innovations. The knitwear we now see from BYBORRE has “outrun“ the knits we knew from sneakers. With the circular knitting technique, what kind of knit innovations will we see ending up in the shoe industry again?

B: Haha, outrun the shoes. The beautiful thing about footwear is that it has a small surface so I believe the most advanced things will end up in footwear. Just wait until we get started!

Apparel is making a shift into more functional wear. Aesthetics are no longer the main driving force in why we buy clothing. We want our clothing to be utilitarian and support us in all the things we encounter daily.

More or less, we all have the same mobile phone. The reason the differentiation in mobile phones has plateaued is because they do more for us. They are an extension of our body. Currently the majority of clothing does one thing for us. BYBORRE’s dream is to create clothing that does more for us. One “suit” that supports us in every scenario. What initiatives in 2020 will you bring to life to take another step towards that dream?

S: I feel that this is a contradiction when operating on the fashion stage. There is this ongoing urge for renewal. We decided to approach this from a constantly evolving point of view. This means that once we’ve produced a version of a garment, we’re continuing to evolve the designs.

We try to make every final expression as precise as possible. If you compare it to the Levi’s 501 or Apple iPhone, when those products first came out, they were the most precise expression of what they could make at that moment. And then look at how those designs evolved over time. That is the same evolutionary way we approach design.

Simultaneously we are developing new fabrics and new ways of working with them. If we have figured out a new method to finish a garment, we’ll want to update the latest version of a design using that new method. The aim is to make pieces timeless, and in their construction they are, but we are always looking at how we can innovate and improve with what our latest developments and ideas are. That's

how evolution works. That being said, we stand by our past expression of pieces.

The concept of the single outfit or single uniform is totally valid and in a sense, we are working on that. BYBORRE has a vision, that if we follow the logical course of where AR and VR are headed, with the evolution of creating fashion digitally, at some point those will come together and everyone will be walking around in mocap suits. And everyone's outfit will be what they show it to be. That is this future vision. Before we reach that point, functionality and comfort is what we are focusing on within the BYBORRE label.

The design challenge is to make something that works for as many different environments and circumstances as possible. Whether the solution to that challenge is a single suit, that remains to be seen. Different situations require different specs in a garment. And we can’t forget that the world is made up of many different environments. One suit to rule them all is a very utopian concept. But it is a dot on the horizon.

Please tell us a little bit about your development in the last couple years and how this has directly translated into your design approach and garments? What is the biggest takeaway?

S: I believe we are now a higher resolution version of the initial concept from when Borre started. These archetypal BYBORRE silhouettes are based on research he did in 2011 with the Dutch national gymnastics team, which was about movement and functionality. We took that as a starting point and have been essentially zooming in ever since and refining this way of working.

BYBORRE’s first ready-to-wear collection titled ‘Generation One’ (2017)

The label allows us to ask the following questions: What if we could make the inside as beautiful as the outside? If the fabric is reversible, how could we make the entire garment reversible? What are the key functionality requirements? How can you wear something that makes the most out of our library of fabrics, combined in a functional patchwork? One example of the outcome of some of these questions was our Weight Map concept, where you have the warmth where you want it with the flexibility where you need it at the same time.

I think we found these solutions only because we made it a point to intentionally and continuously put questions on the table from the beginning. Out in the open, we started to evolve. Now we are at the stage where we are branching out to styles that previously may have not been associated with us. For example, flight jackets, which are super cool to do. It allows us to explore our vision of a classic flight jacket, like the B-15 or MA-1 using our fabrics. We wanted the only unexpected element to be our fabric.

Another example is our overshirt or denim jacket inspired pieces from Edition 7™, which are both styles which people wouldn’t normally associate with a knitted garment. These were really developed to show what is possible with BYBORRE knitted fabrics.

BYBORRE EDITION 7™

There is a common understood knowledge that our label is a part of something bigger. And it has this role to play in our process. There is this strategic way of thinking about every decision that happens through this. And on the other hand, there is an element of making individual pieces to the best of our ability.

The biggest take away is that we transformed the label into an innovation vehicle and showcase for the BYBORRE textiles. Testing and validating the textiles and garments from the yarn to the final garment for the end user.

BYBORRE INSIDE seems to be starting off on the right foot. How far away are we from the next announcement of projects and brands using your knit technology?

S: We see BYBORRE INSIDE as an ingredient brand. The projects announced at ISPO earlier this year are what is ready to be shown to the world. What that meant for us is that all these brands were presenting their products, featuring their TDK developed BYBORRE INSIDE textiles. BYBORRE fabrics became a part of their story.

A BYBORRE INSIDE textile comes with the expectation of performance. We don’t see brands using BYBORRE INSIDE as a collaboration, we see it as brands working with BYBORRE’s TDK process to develop their own unique BYBORRE fabrics. In a sense it’s like GORE-TEX. People want to work with GORE-TEX fabrics because they offer a certain function & quality.

It’s this ingredient brand approach.

Congratulations on all the great projects at this year's ISPO! We saw glimpses of The Dark Ice Project, a collaboration with Japanese fishing brand Daiwa, Descente Allterrain, and many other bits. Can you please tell us a little bit more about these projects?

S: Descente Allterrain is the perfect example of the TDK process. We worked with them previously on a unique 3D™ liner for their iconic Mizusawa Down Jacket. They were so pleased with how it turned out, they came back to develop another textile. They had full control over their materials, from color, material, structure, and artwork, and glided seamlessly through the TDK flow.

Daiwa is an advanced fishing brand from Japan, which created an ISPO Gold Award winning jacket in 2019. They approached us because this year they wanted to put a detachable liner inside it. Next to them going through the TDK process to create their ideal knit fabrics we also helped them with design input for the vest’s silhouette where we applied our Weight Mapping Approach.

The Dark Ice Project is the outlier of the three. A partner of ours, The Woolmark Company, came to us and told us about these three British explorers who have this crazy expedition they are planning which involves doing a trek across The North Pole in the winter time. The Woolmark Company came to us to develop brand new fabrics and silhouettes for the base-layer and mid-layers for the explorer’s kits.

That was the trigger for us to put together a consortium of different specialists in their field (adidas TERREX, GORE-TEX, The Woolmark Company) in order to fully understand each individual piece in their kit and see how we could build a fully functioning kit for their exact needs. It has been a super fun and ground breaking project, which carries a huge responsibility. We were confident in our skills to embark on a project like this and made sure that their kit would be something all three explorers fully trusted. We stand by what we create, and by the partners we create with.

The BYBORRE slogan, “We are not in a hurry; We know that good things take time” impressed us a lot. Can you please explain to us this mindset in this fast and furious world?

B: In times like these where a worldwide pandemic is forcing everyone to stop and is creating a recession of a magnitude never seen before, it is more important than ever that we look at our values and live by them.

It is not that we have all the patience in the world, the contrary to be honest, but we do know that when we present something it is just the start of the next step. It’s just a minor pause where we can start the process again as soon as we have time. When you really take the time and you really invest and try it all, that is when you create something that will last.

Be Patient, and be humble.

What can we expect in the next few years from BYBORRE? What are the next steps to mastering knit?

B: I wish I could look into the future and say that everything is going to be fine. But since we can’t, we’ll do our very best to make it a beautiful place for all.

What Borre and Samuel’s team are working on transcends clothing and fashion. Each piece of BYBORRE fabric is rooted with methodical intent. Through textiles they are enabling game changers and creative thinkers to make a positive impact on the future generation. The team is focused more on the motivation to push the narrative through their actions, rather than the other way around.

From approach to execution, yarn to fabric, day in to day out, BYBORRE leads by example. Championing brand responsibility, sustainability as a requirement - not as an afterthought, and to never stop pushing boundaries. So we ask, what do they truly mean to you?

Interview by Charlie Duong & Adrian Bianco

Studio Photography by Charlie Duong